Navigating Plywood Grains

Follow our guide:

In the Pacific Northwest, our most common sanded and framing plywood are:

- Sanded Plywood

- Structural Plywood

- Oriented Strand Board (OSB)

- Every panel has different characteristics for strength and appearance, but they are all graded on the same rules from the American Plywood Association (APA). The grades, for all that they do, are not much more than a way of telling the user what kind of quality they are buying. The higher the grade, the better the panel.

Sanded Plywood Standards

Understanding the intricate details of sanded plywood standards can be challenging, but with the appropriate guidance, it’s a hurdle easily overcome. The guide below serves as your one-stop resource for navigating the diverse landscape of panel grades, ranging from the premium A-A to the versatile B-D. We delve into industry standards across critical categories, empowering you to make informed decisions every step of the way.

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior or Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- A

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- A

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- 18 boat or sled repairs parallel to grain

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- 18 boat or sled repairs parallel to grain

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Where both faces will be visible

- Cabinets and built in furniture

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Marine grade adhesives can be substituted for many sanded panels, but cost limits the widespread application and availability of these panels.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior or Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- A

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- B

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- 18 boat or sled repairs parallel to grain

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Shim, sled, or router repair with small knots permitted

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- One visible side with strength still important

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Marine grade adhesives can be substituted for many sanded panels, but cost limits the widespread application and availability of these panels.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- A

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- 18 boat or sled repairs parallel to grain

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Tight knot to 1 1/2″ with knotholes less than 1″, sanding defects allowed

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 9/32″

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- One visible side important such as soffits or interior applications

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Marine grade adhesives can be substituted for many sanded panels, but cost limits the widespread application and availability of these panels.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- A

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- D

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- 18 boat or sled repairs parallel to grain

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Knots and knotholes to 2 1/2″ allowed, limited splits permitted.

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- One visible side important such as paneling, built-ins, or shelving

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Marine grade adhesives can be substituted for many sanded panels, but cost limits the widespread application and availability of these panels.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior or Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- B

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- B

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Shim, sled, or router repair with small knots permitted

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Shim, sled, or router repair with small knots permitted

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Utility panel with two solid sides

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Marine grade adhesives can be substituted for many sanded panels, but cost limits the widespread application and availability of these panels.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior or Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- B

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Shim, sled, or router repair with small knots permitted

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Tight knot to 1 1/2″ with knotholes less than 1″, sanding defects allowed

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 9/32″

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Utility panel for containers and truck linings or base for exterior coatings

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Marine grade adhesives can be substituted for many sanded panels, but cost limits the widespread application and availability of these panels.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior or Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- B

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- D

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Shim, sled, or router repair with small knots permitted

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Knots and knotholes to 2 1/2″ allowed, limited splits permitted.

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Utility panel for backing or base shelving

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Marine grade adhesives can be substituted for many sanded panels, but cost limits the widespread application and availability of these panels.

- Yes

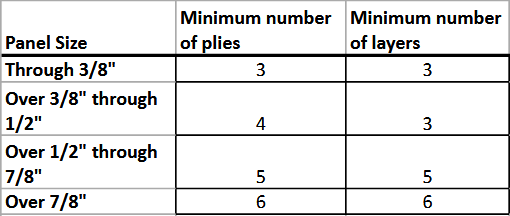

Panel Size

Every panel thickness has a required number of veneer layers based on the grade. The grade will also determine if the panel allows for voids in the core or if the voids must be filled to meet impact resistance in flooring or other high load applications.This chart provides a clear overview of the minimum number of plies and layers required for various plywood panel sizes.

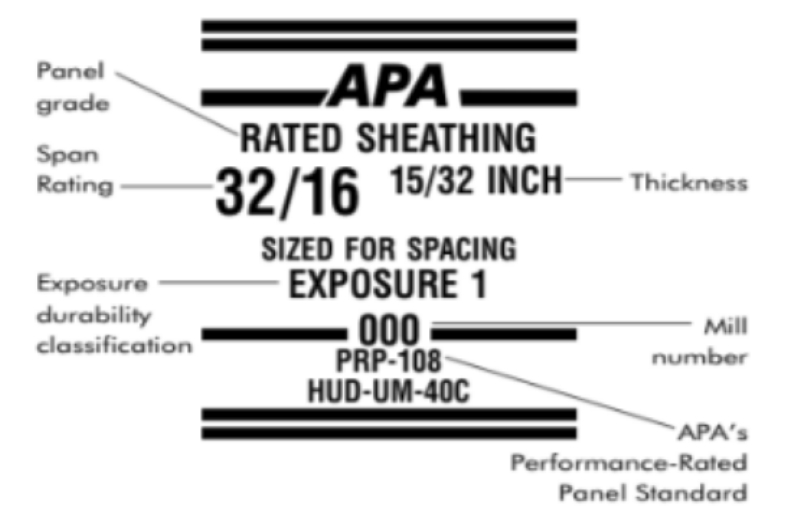

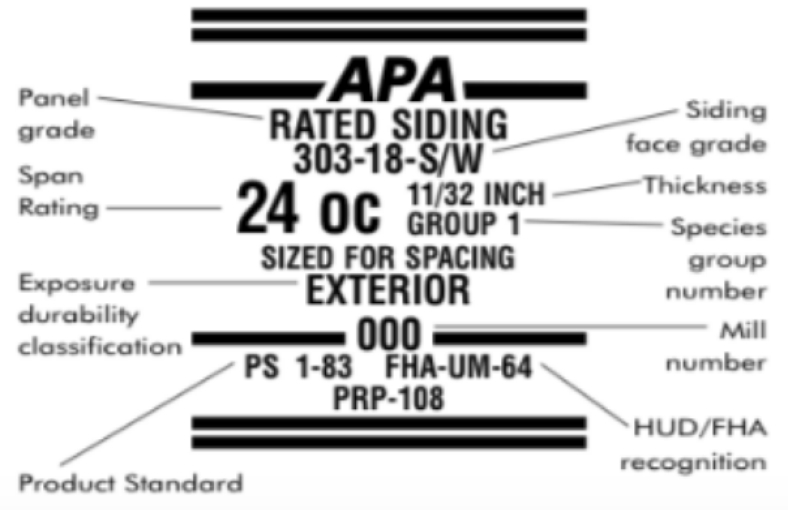

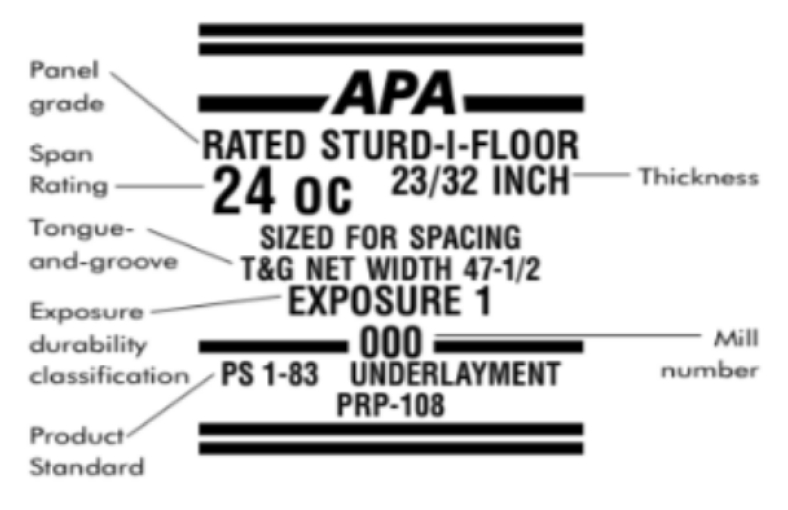

Performance Rated Panel Standards

Performance Rated Panels (PRPs) have revolutionized the construction industry, offering a standardized and reliable way to select plywood and oriented strand board (OSB) sheathing, siding, and subflooring panels. This guide delves into the intricacies of seven key grades:

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- Improved C

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Refers to the maximum distance (in inches) that a Performance Rated Panel (PRP) can safely span between supporting structures (e.g., joists, rafters) without exceeding its bending strength limitations.

- Vary by thickness

Rated for sheathing vs siding vs flooring, factoring in durability in harsh weather conditions or strength and stability. Based on building code compliances.

- Sheathing

Common sizing of the panels is a function of the normal application of the panel.

- 11/32″

- 3/8″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Exterior application where one side is visible and under flooring

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Structural 1 panels are those that support higher cross panel strength and resist racking in structural applications.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Refers to the maximum distance (in inches) that a Performance Rated Panel (PRP) can safely span between supporting structures (e.g., joists, rafters) without exceeding its bending strength limitations.

- Vary by thickness

Rated for sheathing vs siding vs flooring, factoring in durability in harsh weather conditions or strength and stability. Based on building code compliances.

- Sheathing

Common sizing of the panels is a function of the normal application of the panel.

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Exterior application where one side is visible.

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Structural 1 panels are those that support higher cross panel strength and resist racking in structural applications.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior or Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- D

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Refers to the maximum distance (in inches) that a Performance Rated Panel (PRP) can safely span between supporting structures (e.g., joists, rafters) without exceeding its bending strength limitations.

- Vary by thickness

Rated for sheathing vs siding vs flooring, factoring in durability in harsh weather conditions or strength and stability. Based on building code compliances.

- Sheathing

Common sizing of the panels is a function of the normal application of the panel.

- 11/32″

- 3/8″

- 7/16″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Wall or roof sheathing where NO long term exterior exposure exists.

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Structural 1 panels are those that support higher cross panel strength and resist racking in structural applications.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- N/A

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- N/A

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- N/A

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Refers to the maximum distance (in inches) that a Performance Rated Panel (PRP) can safely span between supporting structures (e.g., joists, rafters) without exceeding its bending strength limitations.

- Vary by thickness

Rated for sheathing vs siding vs flooring, factoring in durability in harsh weather conditions or strength and stability. Based on building code compliances.

- Sheathing and Flooring

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 7/16″

- 15/32″

- 19/32″

- 5/8″

- 3/4″

- 7/8″

- 1″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Wall or roof sheathing and subflooring where NO long-term exposure exists.

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Structural 1 panels are those that support higher cross panel strength and resist racking in structural applications.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- B

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- B

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- 303-6 allows 6

- 303-18 allows 18

- 303-30 allows 30

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Refers to the maximum distance (in inches) that a Performance Rated Panel (PRP) can safely span between supporting structures (e.g., joists, rafters) without exceeding its bending strength limitations.

- Vary by thickness

Rated for sheathing vs siding vs flooring, factoring in durability in harsh weather conditions or strength and stability. Based on building code compliances.

- Siding

Common sizing of the panels is a function of the normal application of the panel.

- 11/32″

- 3/8″

- 15/32″

- 1/2″

- 19/32″

- 5/8″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Siding with permanent exposure to weather.

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Structural 1 panels are those that support higher cross panel strength and resist racking in structural applications.

- N/A

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- Improved C

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Refers to the maximum distance (in inches) that a Performance Rated Panel (PRP) can safely span between supporting structures (e.g., joists, rafters) without exceeding its bending strength limitations.

- Vary by thickness

Rated for sheathing vs siding vs flooring, factoring in durability in harsh weather conditions or strength and stability. Based on building code compliances.

- Flooring

Common sizing of the panels is a function of the normal application of the panel.

- 19/32″

- 5/8″

- 23/32″

- 3/4″

- 1″

- 1 1/8″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Subfloor application for high impact floor loads.

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Structural 1 panels are those that support higher cross panel strength and resist racking in structural applications.

- Yes

The bond classification is telling you the type of glue or resin used and how well it holds up to the elements. Ratings include:

Exterior for applications that include many wet and dry cycles that come from long term exposure to the elements

Exposure 1 panels are designed to resist the effects of moisture but are NOT intended for long term exposure to the elements

Exposure 2 panels use interior glue and are intended for use in protected environments.

Interior rated panels are designed for interior use only.

- Exterior or Exposure #1

Thin layer of decorative wood that forms the visible surface on one or both sides of the panel. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- Sanded Face

Thin layer of wood applied to the opposite side of the face veneer. Its primary purpose is to provide structural balance and stability to the panel, preventing warping and twisting. Face and back veneers tell the quality rating of the veneer used in the construction of the panel. While “N” is technically the highest grade, the most common high grade found at a lumber yard will be the “A” grade. Outside of the shop grades, the lowest grade for a rated panel is “D”.

- C

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Face and back patches are the repairs made by the mill to smooth out the graded faces. These repairs can take the following forms:

Boats are football shaped patches

Sleds are wider repairs

Router repairs are used to clean the veneer for a synthetic patch

“C” and “D” grades allow for some holes to remain without repair

- Yes

Repair materials can be wood or synthetic with the specific grades calling out the allowance for the repair type.

- Wood or Synthetic

Refers to the maximum distance (in inches) that a Performance Rated Panel (PRP) can safely span between supporting structures (e.g., joists, rafters) without exceeding its bending strength limitations.

- Vary by thickness

Rated for sheathing vs siding vs flooring, factoring in durability in harsh weather conditions or strength and stability. Based on building code compliances.

- Flooring

Common sizing of the panels is a function of the normal application of the panel.

- 1/4″

- 11/32″

- 3/8″

- 1/2″

- 19/32″

- 5/8″

- 23/32″

- 3/4″

Recommended applications for each grade of plywood. It helps users understand the intended purpose of each grade and select the most suitable one for their project.

- Interior applications for smooth under-carpet or resilient floors.

Panels in the Pacific Northwest are typically produced from Douglas Fir or Pine depending on the mill location and the quality of the veneer being purchased.

- Douglas Fir

- Pine

Structural 1 panels are those that support higher cross panel strength and resist racking in structural applications.

Panel Span Ratings

APA Rated Panels

On APA rated panels, you will see an individual number or set of numbers divided by “/” that indicate the maximum span for the panel in the application. All APA rated Sturd-I-Floor and Siding panels will have a number followed by an O.C. indicating the on-center span.

APA Rated Sheathing Panels

APA rated Sheathing panels will have two numbers that will be a larger number in front of a smaller one that look similar to 32/16 or 48/24. The first number is the roofing span and the second indicates the span in a subfloor application. When the panel is used in a wall application, any rating at 24 and over is used at 24” on-center and anything less than 24 is used at 16” on-center.

Oversized Panels

Some oversized panels built for wall applications will be rated by the APA as sheathing only. The grade stamp will indicate this by rating them at WALL-24 or WALL-16.

Why APA Rated Panels

Building codes are enforced to make sure that a structure protects the occupants in the event of a natural or man-made disaster. The safety of our buildings is accomplished through uniform standards that make it easy to know what is correct. The APA uses uniform testing standards and grading so that you know every panel you install meets the building code and the grade for which you are buying regardless of the mill where it was made.

Some retailers offer mill certified panels as a way to control cost or achieve a standard that they feel is acceptable for their customer base. This standard allows the mill to produce veneers or use adhesives of their own choosing that may or may not meet the building code. The mills also use their own quality standards that may not be in line with the industry standards.

The APA tests and rates panels on the following criteria

- Linear expansion from moisture exposure.

- Racking under a lateral load as part of a complete wall section.

- Uniform load and deflection tested under vacuum.

- Concentrated static load testing deflection and ultimate load between joist or wall sections depending on the application of the panel.

- Concentrated impact load tested by dropping weight onto the panel.

- Direct fastener withdrawal is measured by pulling apart a previously fastened panel.

- Lateral fastener strength is measured by forcing a panel laterally against the fastener.

- Surface profile is measured before and after moisture cycles to determine the stability of the pattern in APA Rated Siding.

- Peel testing is used to determine how well a panel will hold paint or stain.

Common Application

The most common APA panels are performance panels used in framing process of building a structure. Wall and roof sheathing, siding, subflooring, and crating are among the many everyday uses for APA rated panels.

Other specialty panels exist for specific applications like marine and concrete forming. Specific design criteria and limitations can be found on the APA website for these and many other special uses.

Whatever panel you choose, knowing the grade will help you determine if it is right for your project. Grading used in conjunction with your design will help make sure that your project lasts for as long as you want it to. All you have to do now is insist on rated panels.

For more information on the APA – The Engineered Wood Association rules on panels and grading standards, please visit the APA – The Engineered Wood Association www.apa.org.